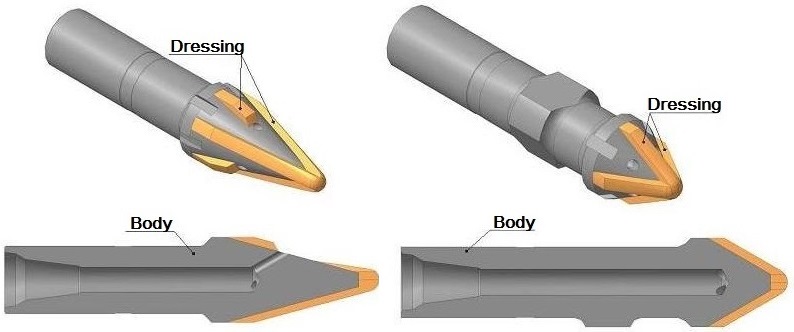

Tools for sidetracking. Fishing, milling and cleaning equipment. Tools for coiled tubing units.

About company

More info »

“BITTEKHNIKA” LLC was founded in 1996. Through all these years of successful experience we have developed a sustainable manufacturing system of oilfield equipment.

News

All news »

3 November 2023

Exhibitor of 2023 ADIPEC

Address: 395 Ya, Shosse Kosmonavtov Str., Perm, Russia, 614065

Phone: +7 (342) 27-000-27, 294-64-64

E-mail: info@bittekhnika.ru, sales@bittekhnika.ru, pr@bittekhnika.ru

© BITTEKHNIKA, LLC

2018. All rights reserved.

2018. All rights reserved.

Создание сайта Amado